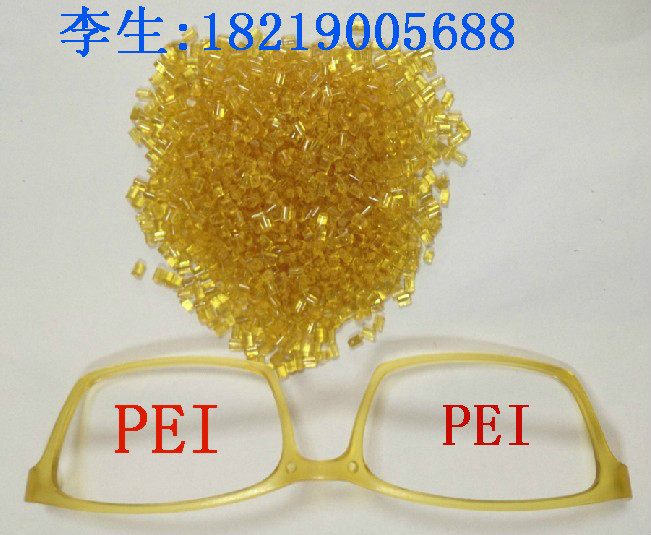

ULTEMTM 1000 樹脂是一種無形的、透明polyetherimide(PEI)塑料提供玻璃轉變溫度(Tg)217°C。這種固有的阻燃樹脂UL94爆破,V2和5弗吉尼亞州評級,并通過無鉛認證。ULTEMTM 1000樹脂是一種無筋通用級提供耐高溫、高強度和模量和廣泛的化學耐高溫。 1000,1000E,1000F,1000P,1000R,1000RV.

ULTEM ? Resin 1000

SI

| British

| Metric

| PDF

Americas: COMMERCIAL

ULTEMTM 1000 resin is an amorphous, transparent polyetherimide (PEI) plastic offering a glass transition temperature (Tg) of 217°C. This inherently flame retardant resin has UL94 V0, V2 and 5VA ratings and is RoHS compliant. ULTEMTM 1000 resin is an unreinforced general purpose grade offering high heat resistance, high strength and modulus and broad chemical resistance up to high temperatures.

Property

TYPICAL PROPERTIES (1)

MECHANICAL

Value

Unit

Standard

Tensile Stress, yld, Type I, 5 mm/min

1120

kgf/cm2

ASTM D 638

Tensile Strain, yld, Type I, 5 mm/min

7

%

ASTM D 638

Tensile Strain, brk, Type I, 5 mm/min

60

%

ASTM D 638

Tensile Modulus, 5 mm/min

36500

kgf/cm2

ASTM D 638

Flexural Stress, yld, 2.6 mm/min, 100 mm span

1680

kgf/cm2

ASTM D 790

Flexural Modulus, 2.6 mm/min, 100 mm span

35800

kgf/cm2

ASTM D 790

Hardness, Rockwell M

109

-

ASTM D 785

Taber Abrasion, CS-17, 1 kg

10

mg/1000cy

ASTM D 1044

IMPACT

Value

Unit

Standard

Izod Impact, unnotched, 23°C

136

cm-kgf/cm

ASTM D 4812

Izod Impact, notched, 23°C

5

cm-kgf/cm

ASTM D 256

Izod Impact, Reverse Notched, 3.2 mm

136

cm-kgf/cm

ASTM D 256

Gardner, 23°C

373

cm-kgf

ASTM D 3029

THERMAL

Value

Unit

Standard

Vicat Softening Temp, Rate B/50

218

°C

ASTM D 1525

HDT, 0.45 MPa, 6.4 mm, unannealed

210

°C

ASTM D 648

HDT, 1.82 MPa, 6.4 mm, unannealed

201

°C

ASTM D 648

CTE, -20°C to 150°C, flow

5.58E-05

1/°C

ASTM E 831

CTE, -20°C to 150°C, xflow

5.4E-05

1/°C

ASTM E 831

Thermal Conductivity

0.22

W/m-°C

ASTM C 177

Relative Temp Index, Elec

170

°C

UL 746B

Relative Temp Index, Mech w/impact

170

°C

UL 746B

Relative Temp Index, Mech w/o impact

170

°C

UL 746B

PHYSICAL

Value

Unit

Standard

Specific Gravity

1.27

-

ASTM D 792

Water Absorption, 24 hours

0.25

%

ASTM D 570

Water Absorption, equilibrium, 23C

1.25

%

ASTM D 570

Mold Shrinkage, flow, 3.2 mm (5)

0.5 - 0.7

%

SABIC Method

Melt Flow Rate, 337°C/6.6 kgf

9

g/10 min

ASTM D 1238

ELECTRICAL

Value

Unit

Standard

Volume Resistivity

1.E+17

Ohm-cm

ASTM D 257

Dielectric Strength, in air, 1.6 mm

32.7

kV/mm

ASTM D 149

Dielectric Strength, in oil, 1.6 mm

27.9

kV/mm

ASTM D 149

Dielectric Strength, in oil, 3.2 mm

19.6

kV/mm

ASTM D 149

Relative Permittivity, 100 Hz

3.15

-

ASTM D 150

Relative Permittivity, 1 kHz

3.15

-

ASTM D 150

Dissipation Factor, 100 Hz

0.0015

-

ASTM D 150

Dissipation Factor, 1 kHz

0.0012

-

ASTM D 150

Dissipation Factor, 2450 MHz

0.0025

-

ASTM D 150

Arc Resistance, Tungsten {PLC}

5

PLC Code

ASTM D 495

Hot Wire Ignition {PLC)

1

PLC Code

UL 746A

High Voltage Arc Track Rate {PLC}

2

PLC Code

UL 746A

High Ampere Arc Ign, surface {PLC}

3

PLC Code

UL 746A

Comparative Tracking Index (UL) {PLC}

4

PLC Code

UL 746A

FLAME CHARACTERISTICS

Value

Unit

Standard

UL Recognized, 94V-2 Flame Class Rating (3)

0.4

mm

UL 94

UL Recognized, 94V-0 Flame Class Rating (3)

0.75

mm

UL 94

UL Recognized, 94-5VA Rating (3)

3

mm

UL 94

Oxygen Index (LOI)

47

%

ASTM D 2863

NBS Smoke Density, Flaming, Ds 4 min

0.7

-

ASTM E 662

Source GMD, last updated:2015/01/12

Processing

Parameter

Injection Molding

Value

Unit

Drying Temperature

150

°C

Drying Time

4 - 6

hrs

Drying Time (Cumulative)

24

hrs

Maximum Moisture Content

0.02

%

Melt Temperature

350 - 400

°C

Nozzle Temperature

345 - 400

°C

Front - Zone 3 Temperature

345 - 400

°C

Middle - Zone 2 Temperature

340 - 400

°C

Rear - Zone 1 Temperature

330 - 400

°C

Mold Temperature

135 - 165

°C

Back Pressure

0.3 - 0.7

MPa

Screw Speed

40 - 70

rpm

Shot to Cylinder Size

40 - 60

%

Vent Depth

0.025 - 0.076

mm

Parameter

Extrusion Blow Molding

Value

Unit

Drying Temperature

140 - 150

°C

Drying Time

4 - 6

hrs

Drying Time (Cumulative)

24

hrs

Maximum Moisture Content

0.01 - 0.02

%

Melt Temperature (Parison)

320 - 355

°C

Barrel - Zone 1 Temperature

325 - 350

°C

Barrel - Zone 2 Temperature

330 - 355

°C

Barrel - Zone 3 Temperature

330 - 355

°C

Barrel - Zone 4 Temperature

330 - 355

°C

Adapter - Zone 5 Temperature

330 - 355

°C

Head - Zone 6 - Top Temperature

330 - 355

°C

Head - Zone 7 - Bottom Temperature

330 - 355

°C

Screw Speed

10 - 70

rpm

Mold Temperature

65 - 175

°C

Die Temperature

325 - 355

°C

Compare

Contact Us

ULTEM? Resin

Grades

De

1000

ULTEMTM 1000 resin is an amorphous, transparent polyetherimide (PEI) plastic offering a glass transition temperature (Tg) of 217°C. This inherently flame retardant resin has UL94 V0, V2 and 5VA ratings and is RoHS compliant. ULTEMTM 1000 resin is an

Datasheet

Product Data: Engineering Design Data | Chemical Compatibility

Auto Data: Auto Specification

1000E

Transparent, standard flow Polyetherimide (Tg 217C) with internal mold release. ECO Conforming. US FDA and EU Food Contact compliant, NSF 51 Listing.

Datasheet

Product Data:

Auto Data:

1000F

ULTEMTM 1000F resin is an amorphous, transparent polyetherimide (PEI) plastic offering a glass transition temperature (Tg) of 217°C. This inherently flame retardant resin has UL94 V0, V2 and 5VA ratings and is RoHS, US FDA and EU Food Contact complia

Datasheet

Product Data: | Chemical Compatibility

Auto Data:

1000P

Standard flow Polyetherimide (Tg 217C) in 350 micron powder. ECO Conforming.

Datasheet

Product Data:

Auto Data:

1000R

Opaque, standard flow Polyetherimide (Tg 217°C). Resin is RoHS compliant. UL94 V0, V2 and 5VA listing.

Datasheet

Product Data: Engineering Design Data

Auto Data: Auto Specification

1000RV

Standard flow Polyetherimide (Tg 217C) with internal mold release. ECO Conforming, UL94 V0 and 5VA listing; color dependant, see UL Yellow Card.

Datasheet

Product Data:

Auto Data:

1010

ULTEMTM 1010 resin is an amorphous, transparent polyetherimide (PEI) plastic offering enhanced flow and a glass transition temperature (Tg) of 217°C. This inherently flame retarant resin has UL94 V0 and 5VA ratings. ULTEMTM 1010 resin is an unreinfor

Datasheet

Product Data: Engineering Design Data | Chemical Compatibility

Auto Data: Auto Specification | Color Specification

1010F

Transparent, easy flow Polyetherimide (Tg 21°7C). Resin is RoHS compliant. UL94 V0 and 5VA listing. US FDA and EU Food Contact compliant.

Datasheet

Product Data:

Auto Data:

1010M

Transparent, enhanced flow Polyetherimide (Tg 21°7C) with internal mold release. Resin is RoHS compliant.

Datasheet

Product Data: Engineering Design Data

Auto Data: Auto Specification

1010P

Enhanced flow Polyetherimide (Tg 217C) in 350 micron powder. ECO Conforming.

Datasheet

Product Data:

Auto Data:

1010R

Enhanced flow Polyetherimide (Tg 217C) with internal mold release. ECO Conforming, UL94 V0 and 5VA listing.

Datasheet

Product Data: Engineering Design Data

Auto Data: Auto Specification

1100

Standard flow Polyetherimide (Tg 217C). ECO Conforming, UL94 V0, V2 and 5VA listing.

Datasheet

Product Data:

Auto Data:

1100F

Standard flow Polyetherimide (Tg 217C). ECO Conforming. US FDA and EU Food Contact compliant. UL94 V0, V2 and 5VA listing.

Datasheet

Product Data:

Auto Data:

1110

Enhanced flow Polyetherimide (Tg 217C). ECO Conforming.

Datasheet

Product Data:

Auto Data:

1110F

Enhanced flow Polyetherimide (Tg 217C). ECO Conforming. US FDA and EU Food Contact compliant, NSF 51 listing. UL94 V0 and 5VA listing.

Datasheet

Product Data: Engineering Design Data

簡繁切換

簡繁切換